Bartlett Architecture students fuse glass and metal to create innovative building skin

)

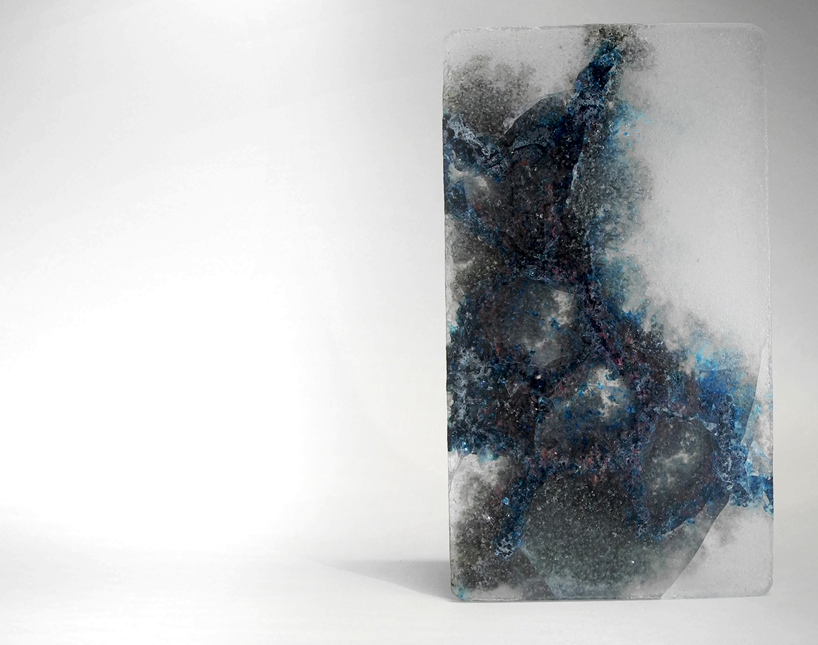

Students at the Bartlett School of Architecture, part of University College London, explored fusing glass with metal at an architectural scale to create building skins that are continuous and discrete.

The student team consisting of Ainaini Rahin, Sun Meng Yan, Jian Fei, led by the tutor Kostas Grigoriadis, wanted to propose a new multi-material that enables a more direct, immediate and orderly building technique, forgoing the current practice of messy tectonic assemblages.

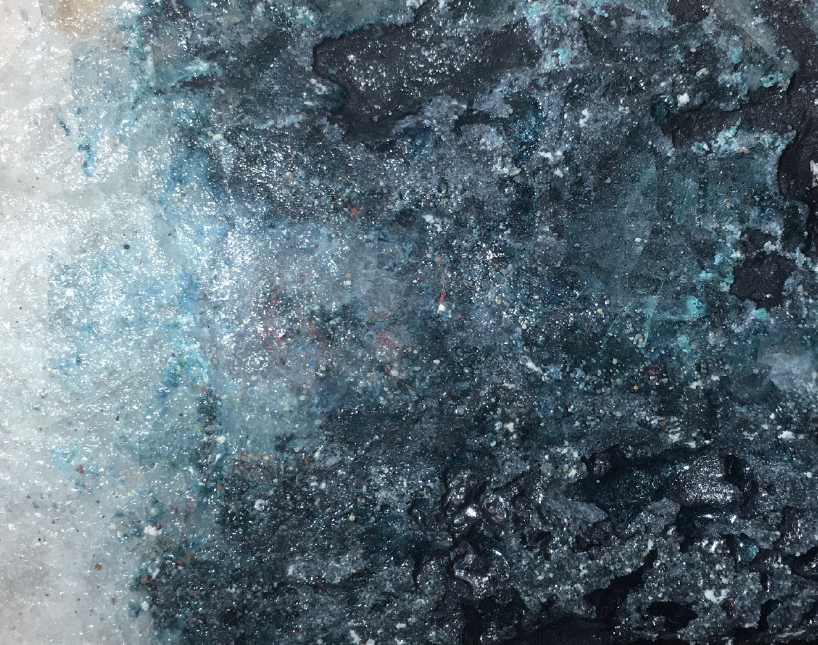

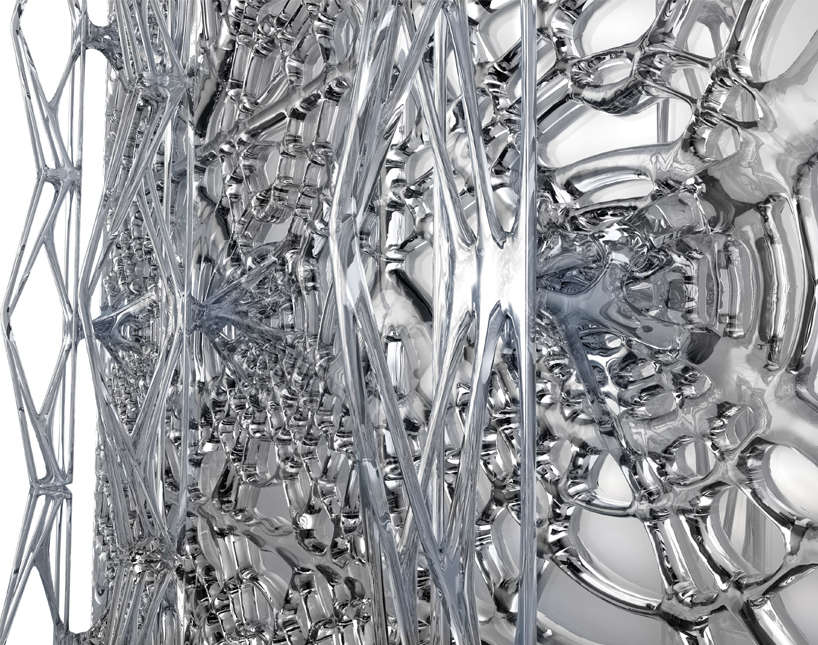

Close-up view of metal and bullseye glass frits functionally graded material study model.

'

The project investigates the construction of a singular secretion of a variably continuous multi-material, consisting of transparent, translucent, opaque and structural insulating sub-materials. In architecture, this idea of graded materiality promises a fundamental shift in how elements come together, opening up a whole new discussion in the understanding of constructs as continuous fields consisting of diverse materiality varied on a local level.

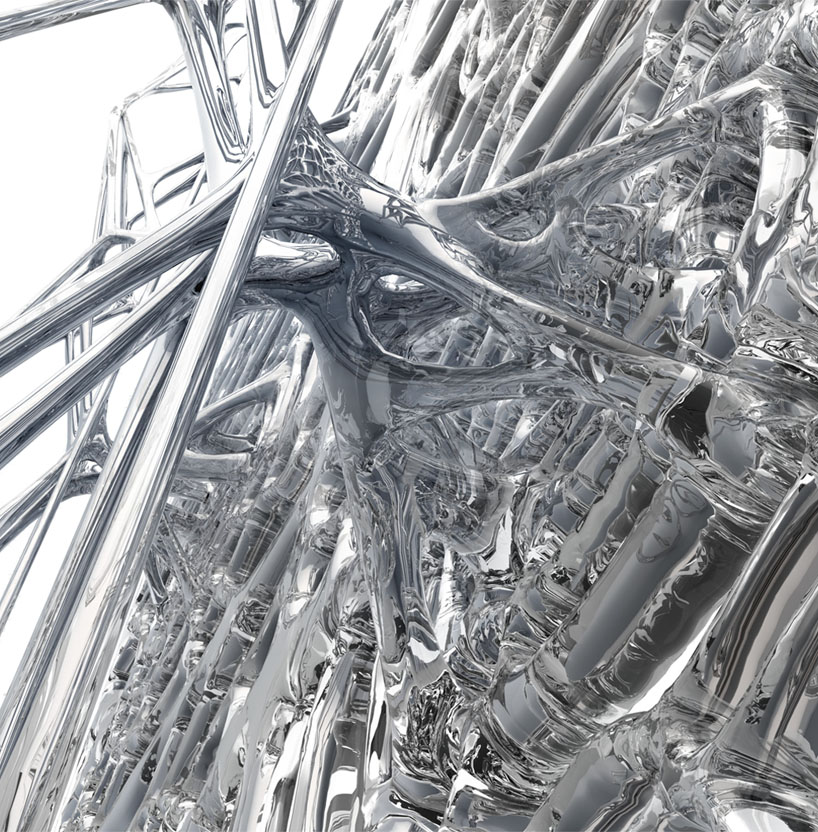

Gradient of glass and metal fluids that fuse within a certain period of time.

'

One of the main issues the students encountered when fusing glass with metal in an architecture scale was the firing process and keeping the gradient accurate when following the computational simulation results.''In order to fire the glass and metal as a building as one continuous monolith, as is usually done in small-scale prototype, the firing method has been developed and adjust to the scale using computer simulation then transfer it to the actual model.'

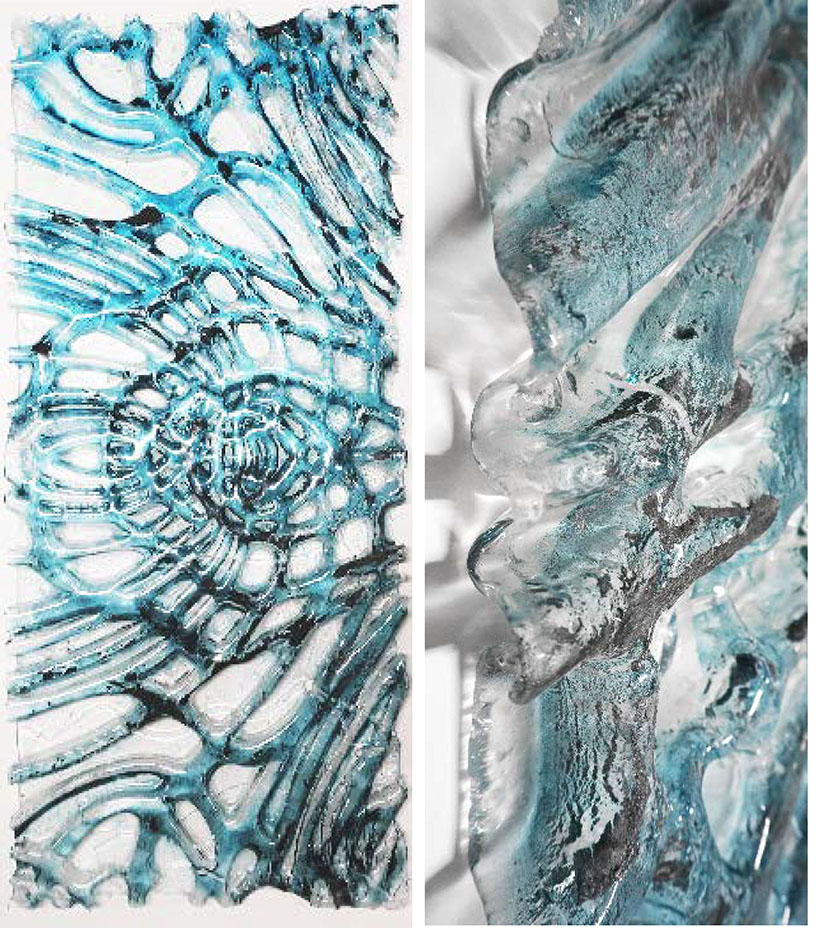

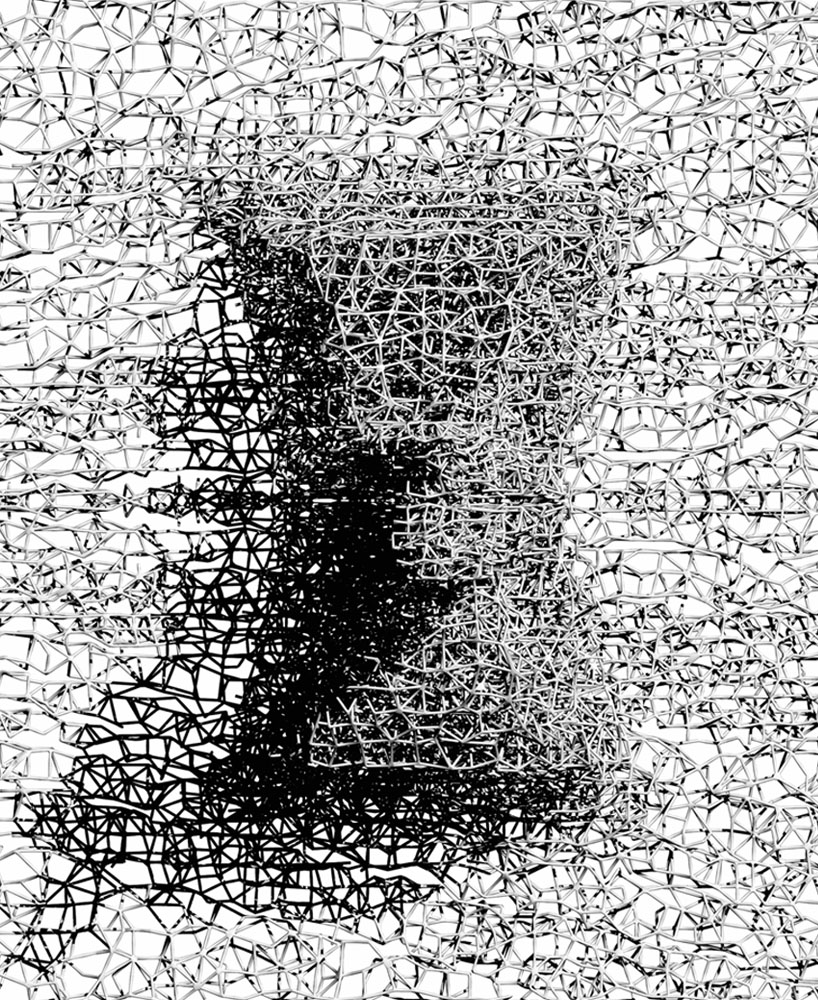

Frontal and side views of the functionally graded material model where the exterior glass skin was topologically optimised.

'

Although many architects and designers are developing techniques to efficiently 2D print structures, the team realised that'3D printing'a whole structure in a fluid gradient was nearly impossible due to limitations in the fabrication process. However, they managed to mix the computational method during the first phase of the research, with fabricating the building skin manually. They believe their method could be used to fuse elements in 3D such as a floor-wall-ceiling assembly or a stair-floor-wall component as 'one whole architectural chunk.'

Close-up view of the functionally graded material glass model.

'

The team presented the functionally-graded curtain wall at the b-pro Bartlett show, which took place in September and October 2018. The group now hopes to develop its technique to produce other architectural elements with different properties and functions. 'one of the next steps for the project would be to continue to explore the multi-material aspect: developing the combination of the two materials for a building facade.'' The students' ultimate aim is to go against the discrete construction and to develop new materials and techniques to create large-scale structures.

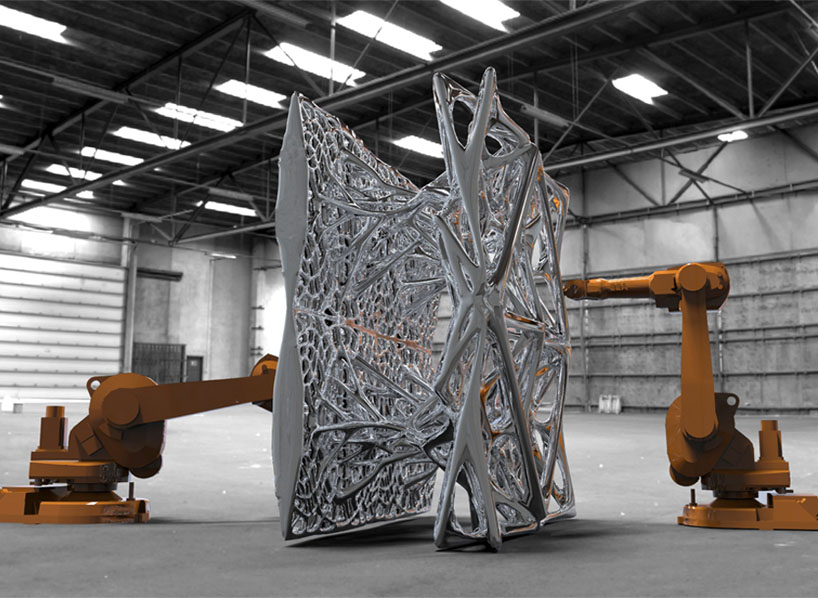

The aim of the research is to go against the discrete construction.

Rendered detail studies of the graded multiple point connection between the glass and metal sub-materials of the multi-material envelope.

Close-up details of the rendered graded multiple point connection between the glass and metal sub-materials of the multi-material envelope.

Frontal view of the porosity study render of the graded building envelope's substructure.

Porosity study render of the graded building envelope's substructure.

B-pro show at the Bartlett School of Architecture, UCL.

Source: designboom

London Build is the leading building & construction show for London and the UK. Gain access to 350+ exhibitors, 500+ speakers and connect with 25,000+ registered visitors. If you are interested in speaking, exhibiting or becoming an official event partner for the 2019 show, simply submit your interest and a member of the team will be in touch.'

.png)